Minimizing Swimming Pool Structural Problems Due to Concrete Deck Construction

Expansion and Contraction in Concrete Construction

Most of us in the swimming pool construction industry know that many materials expand and contract with temperature change. How many of us know how important proper trade practices are in minimizing problems due to temperature caused expansion and contraction? For example, concrete is one of the most highly utilized materials in our industry today, yet I consistently see swimming pools damaged by expansion and contraction of adjacent concrete flatwork.

The most important bit of information to remember is the expected expansion in concrete caused by temperature change. Between the heat of summer (pool deck surface at 130º to 140º) and the dead of winter (pool deck surface at 30º to 40º) we can expect at least a 100º temperature change. The critical number to remember is that a 100 foot wide section of concrete will expand approximately 3/4 of an inch with a 100º temperature change. The expansion in lesser widths of concrete can be easily determined by proportioning the 3/4“ per 100 feet. The force of expanding concrete is very high and can easily shear off the coping or bond beam without properly installed isolation joints.

Mastic Joints

The mastic joint between the swimming pool concrete decking and the pool coping/bond beam is an extremely important component of a swimming pool and must be properly installed. The purpose of this joint is to isolate concrete deck movement from the pool coping/bond beam assembly. As discussed above, concrete flatwork including pool decks expand and contract with temperature change (up to 100° of variation can be expected). Without the installation (and proper maintenance) of a flexible mastic joint between the swimming pool decking and the pool coping, movement caused by expansion and contraction of the pool deck will frequently cause dislodged coping, tile and horizontal cracking in the water line tile. This mastic joint must extend the full depth of the concrete decking so that no portion of the concrete deck can apply pressure against the coping or any portion of the pool structure.

A diagram indicating proper construction joint technique and the effects of improper joint techniques is accompanying labeled as exhibit “A.” As indicated on the accompanying diagram, dislodging of the pool coping, horizontal cracking in the water line tile and shearing of the bond beam is frequently the result of improper installation of the mastic joint. Proper installation of the mastic joint is normally the responsibility of the concrete pool decking installer.

The lack of adequate maintenance of the mastic joint may result in a loss of expansion protection and can cause the same problems that are experienced without the installation of the mastic joint.

Cantilevered Concrete Pool Decking

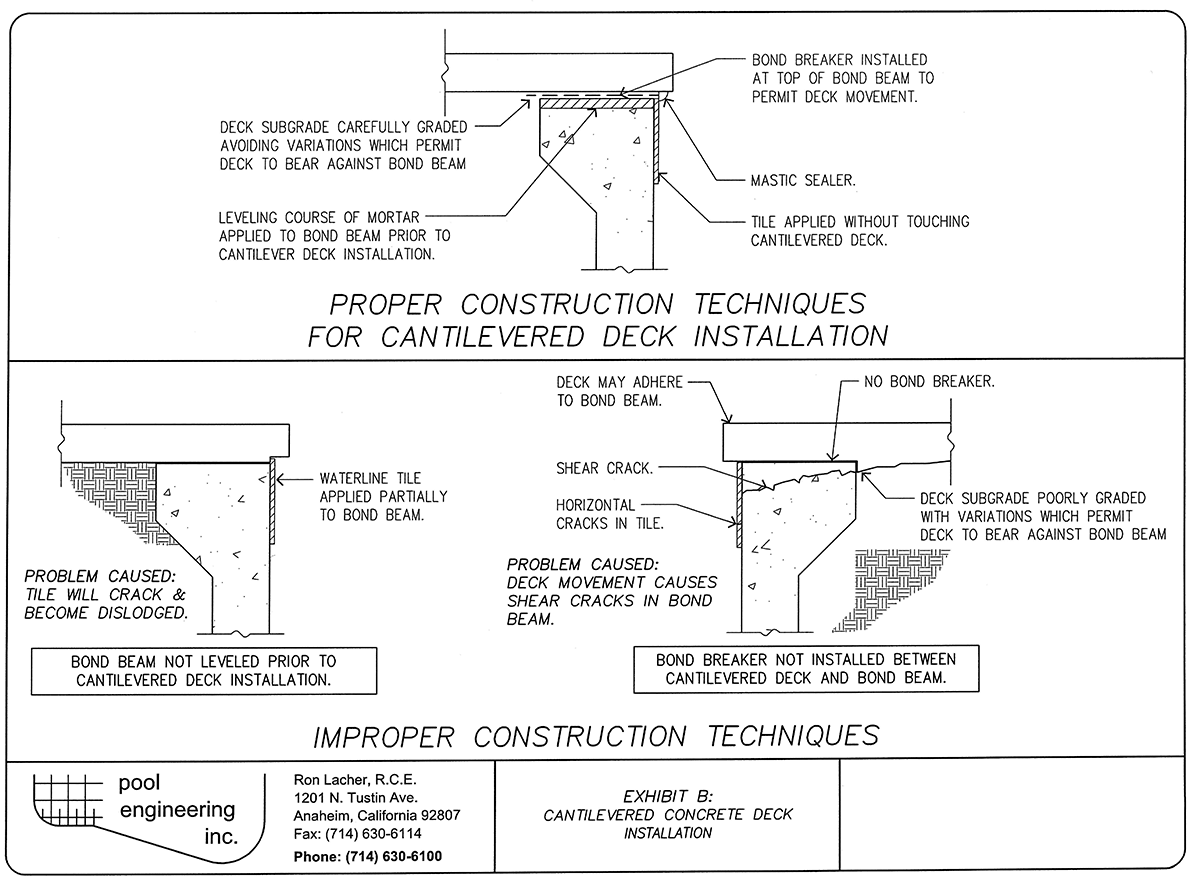

Cantilevered concrete pool decking must also be properly installed to isolate concrete deck movement due to temperature expansion and other causes from the pool coping/bond beam assembly. The proper construction techniques basically requires the leveling of the top of the bond beam and then the installation of a bond breaker or slip joint on top of the leveled beam prior to pouring the concrete deck. This is shown on the accompanying diagram labeled exhibit “B.” By not following the proper construction techniques, the waterline tile may become partially applied to the cantilevered deck (which will result in horizontal cracks in the tile) or deck movement may shear off the leveling mortar course or the top of the bond beam. The result of improper construction techniques is also shown on exhibit “B”.

No steel reinforcing should be extended from the bond beam into the pool deck. Further, the new cantilevered concrete deck should have no direct contact with the bond beam of the pool especially immediately behind the bond beam.

Bonding of the Leveling Course of Mortar

Reoccurring horizontal cracking and dislodging of the water line tile can also be caused by the unbonding of the mortar or concrete layer used to level the top of the bond beam elevation prior to coping or cantilevered concrete deck application. This unbonding, most likely, has been caused by improper construction techniques used in the application of the mortar or concrete layer to the top of the lower bond beam elevation.

It is very important that correct procedures be followed to assure proper bond of this mortar course to the existing bond beam. The following are recommendations on correct construction techniques for attaining proper bonding of new materials such as masonry, tile, gunite and concrete to existing similar materials:

- Existing surfaces must be sound, free of defects, clean and free of bond inhibiting materials.

- Existing surfaces must be roughened by chipping or other suitable means to provide an open pore structure. All loose, cracked or deteriorated materials must be removed.

- Clean existing surfaces by water blasting.

- New material should be applied over cement paste or another approved bonding agent, which has been brushed onto the substrate (existing material) for absorption into the pore structure. The new material shall be applied before the cement paste or other approved bonding agent “skins over” or starts its “setting stage.”

- Saturated surface dry condition of the substrate shall be maintained to prevent premature drying of the bonding paste.

Following these recommended practices will minimize problems in attaining proper bonding between these materials and will provide quality results.

We’re a small family firm but recognized nationally as the experts in both Swimming Pool Structural Design, and Swimming Pool Construction and Trade Practice.

We help you learn the right way to build pools through articles and seminars on every aspect of pool construction.